Underwater Welding - The Facts?

Underwater Welding - The Facts?

Blog Article

Walking the cup is a simple, but very effective way to TIG weld. It creates a very consistent weld with genuinely uniform skin. The reason behind this is user-friendly. The arc length and the pattern used are nearly always the common. Walking the cup eliminates most handshakes and wobbles because the cup with the TIG torch is always leaning towards the metal.

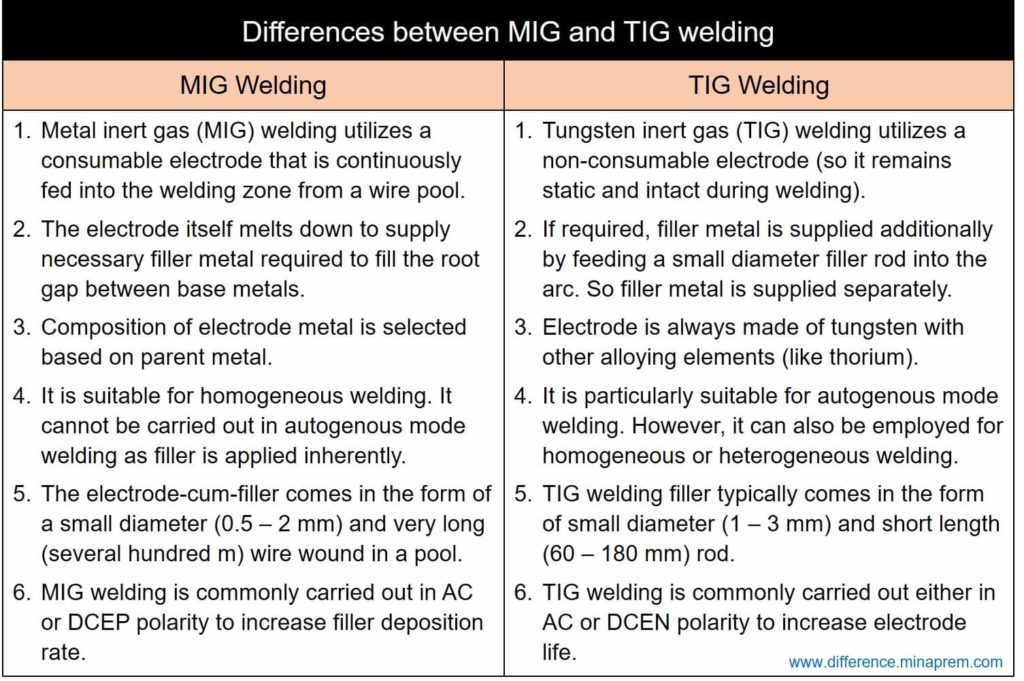

Using a mig or tig welder requires more skill but in a manner is similar to using the Oxy-Acetylene gas process. tig welders use a small gadgets torch that carries a tungsten electrode to create the arc. Tungsten is used as there's an extremely high melting goal. The tungsten tip, when struck to the metal produces the arc and begins the fusion process; at now a filler rod is introduced include substance to the joint. This is where the operator needs a comfortable hand.

mig vs tig welding is popular in the powerhouse industry and in petro chemical plants. Will be widely employed the fabrication of lightweight bicycles. There thousands of uses to do this kind of welding. Special aspect on that welding procedure is that it really absolutely takes into consideration the format of needing to use hands while utilizing the weld along with the weld is fairly clean.

Anyway, she asked me how old my baby is now and I thought, 'oh god, she's looking at me and thinking I've just given birth!' She's spotted my pathetically untoned bits (bits implies only parts of me are untoned. Let's just assume that's true eh?) and thought 'she's probably got a little baby merely takes a simple couple of weeks old'.

Push don't pull - Pushing increases results and allows the metal to be cleaned by the arc. Pulling results in soot. But in case you need to use pulling, you should clean function area employing a stainless steel brush just before welding.

Assuming there is not any old spool of MIG wire throughout the MIG welder. The first think you want to do is physically open the mig vs tig welding machine or wire feed case up.

Use correct shielding the cost of gas. Co2 gas is good for penetration; however it would possibly burn hot on lighter gauge mining harvests. In this case opt for with the multitude of 75% argon and 25% co2. If welding Aluminium use pure argon systems don't always.

For overhead welding, the idea look prefer a series of backwards C's. depending for your direction. No matter what position or what regarding weld, dust and grime. Report this page